At the Centre of Intelligent Manufacturing (CIM), we are redefining the future of maritime propulsion systems with advanced propeller design techniques. Our approach combines cutting-edge technologies and sustainable practices to create propellers that enhance vessel performance, reduce fuel consumption, and minimize environmental impact.

Our Approach

Our propeller design process integrates state-of-the-art tools and methodologies to deliver high-performance solutions tailored to the unique requirements of each vessel:

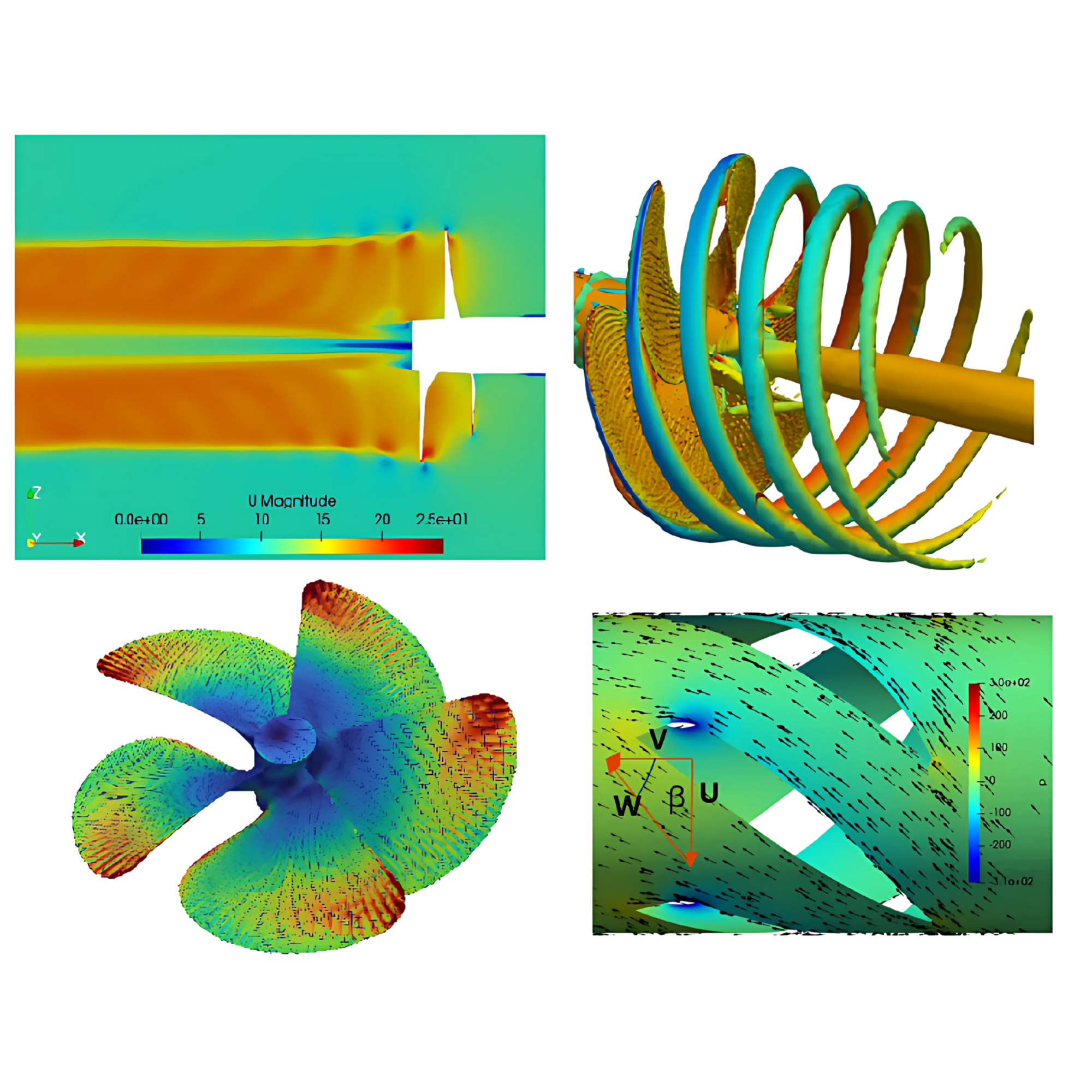

- Parametric Modeling:

We use parametric modeling to create flexible and precise digital representations of propeller geometries. This approach allows us to explore a wide range of design variations efficiently, ensuring optimal performance for different vessel types and operating conditions.

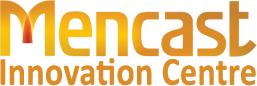

2. Computational Fluid Dynamics (CFD):

CFD simulations play a critical role in analyzing and optimizing propeller performance. By simulating fluid flow around the propeller, we can evaluate key performance metrics such as thrust, efficiency, and cavitation resistance, ensuring that each design meets the highest standards of functionality and durability.

3. Generative AI and Machine Learning:

Leveraging generative AI and machine learning algorithms, we explore innovative design possibilities beyond traditional approaches. These technologies enable us to identify optimal design configurations, streamline the iterative design process, and predict performance outcomes with remarkable accuracy.

4. Optimization Techniques:

Our optimization tools consider multiple variables, including blade shape, pitch, skew, and rake, to achieve the perfect balance between thrust, efficiency, and noise reduction. This results in propellers that enhance vessel speed without compromising environmental goals.

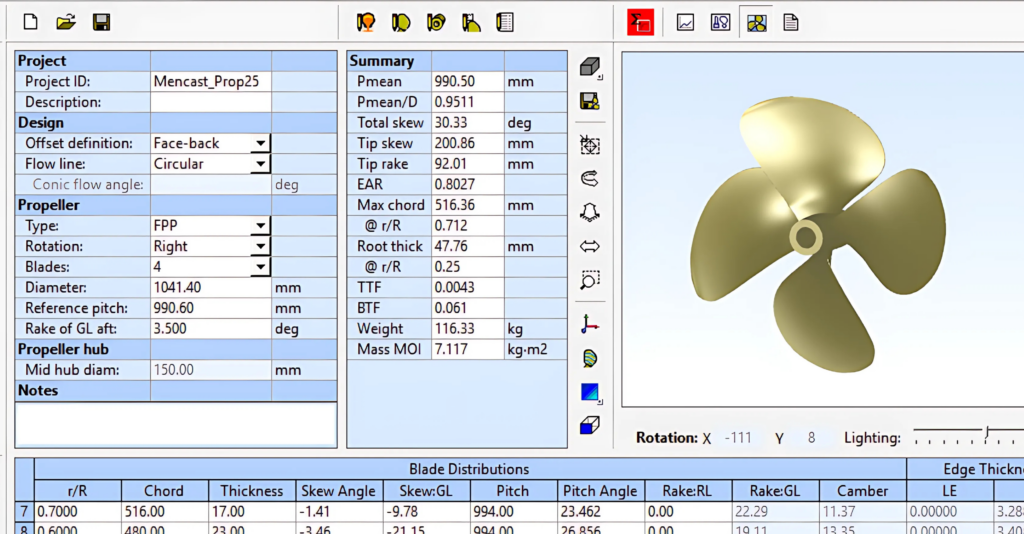

Sustainability at the Core

At CIDM, we are committed to supporting the global transition toward greener shipping. Our propeller designs aim to:

- Increase Fuel Efficiency: By reducing hydrodynamic resistance, our propellers help vessels achieve higher speeds with lower fuel consumption, reducing operational costs and greenhouse gas emissions.

- Minimize Carbon Footprint: Through innovative design techniques, we contribute to sustainable maritime operations, helping vessels comply with stricter environmental regulations.

- Support Faster Vessel Speeds: Our designs allow ships to operate more efficiently, meeting the demands of modern logistics while promoting eco-friendly practices.

Applications

Our advanced propeller designs are suitable for a wide range of vessels, including:

- Fast crew boats

- Passenger ferries

- Tug boats

- Research vessels

- Offshore supply vessels

Visualizing the Future

Our expertise extends to 3D modeling and rendering, enabling us to visualize propeller designs in the context of vessel operations. This allows us to collaborate closely with shipbuilders, naval architects, and other stakeholders to ensure seamless integration and optimal performance.

Achievements and Impact

- Fuel Savings: Proven reductions in fuel consumption and operational costs for vessel operators.

- Environmental Benefits: Lower emissions, reduced cavitation noise, and compliance with IMO regulations.

- Performance Enhancement: Improved thrust and speed capabilities without increasing engine power requirements.

Collaborate with Us

CIDM is committed to advancing the maritime industry through innovation in propeller design. Whether you’re looking to retrofit an existing vessel or develop a state-of-the-art ship, we have the expertise to deliver customized solutions that align with your goals.

By combining engineering precision, advanced simulation tools, and a focus on sustainability, we are setting a new standard in propeller design. Join us in shaping the future of maritime propulsion systems.