Our manufacturing capabilities go beyond the conventional. But they stand on the shoulders of our craftsmanship heritage.

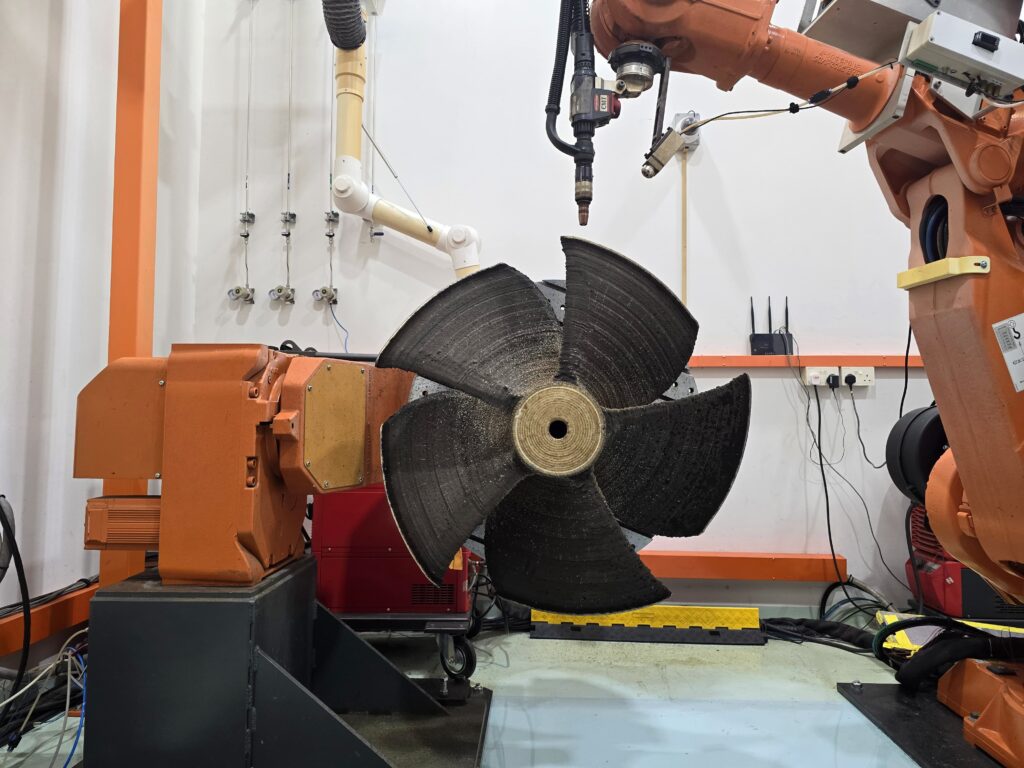

Mencast leverages Wire Arc Additive Manufacturing (WAAM), laser-based metal printing, and hybrid manufacturing techniques to produce complex marine components that would be impossible or highly costly to make using traditional casting alone.

Benefits of Additive Manufacturing for Propellers:

- Freedom to create optimized blade geometries designed by AI

- Stronger, lighter, and more durable components

- Reduction of material waste by up to 80%

- Shorter production lead times

- Rapid prototyping for faster product validation

We are not abandoning what works — we are enhancing it with precision and flexibility.

AI & IoT-Enabled Operations

Mencast integrates IoT sensors and Edge AI within our manufacturing processes to ensure real-time monitoring and data-driven quality control.

Capabilities:

- Continuous tracking of key manufacturing parameters

- Early detection of defects or deviations

- Data-driven insights for predictive maintenance

- Real-world performance monitoring of propellers in service

The same attention to quality we practiced by hand is now amplified with digital intelligence.