At the Centre of Intelligent Design & Advanced Manufacturing (CIDAM), we leverage the power of Artificial Intelligence (AI) and the Internet of Things (IoT) to drive innovation, enhance manufacturing processes, and improve operational efficiency. By integrating cutting-edge technologies into our workflows, we are revolutionizing how data is utilized to ensure precision, quality, and sustainability in maritime manufacturing.

Our Approach

CIDAM’s AI & IoT initiatives focus on optimizing manufacturing operations and creating a secure, intelligent infrastructure to support advanced technologies:

- Real-Time Quality Monitoring and Control:

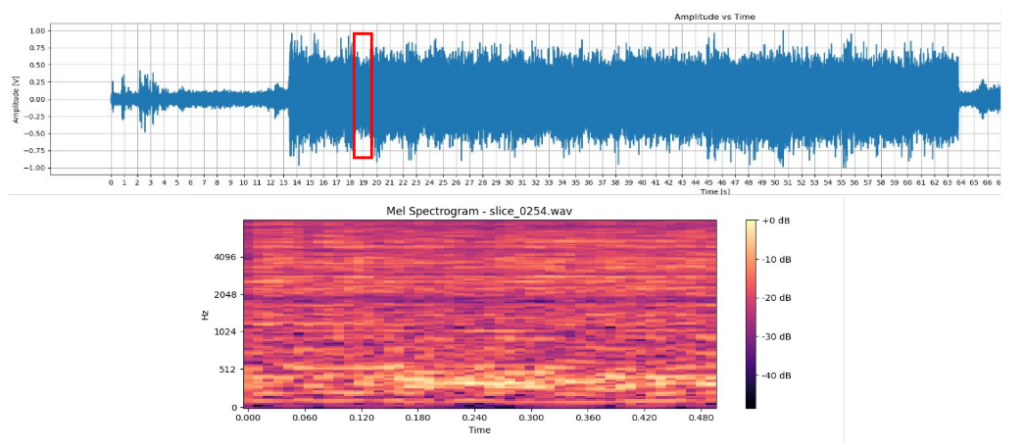

Using IoT sensors and Edge AI, we enable real-time monitoring of additive manufacturing (AM) processes. Sensors, such as photodiodes, microphones, cameras, and infrared thermometers, capture data during metal deposition, allowing us to detect anomalies and defects in real-time. This ensures consistent product quality and reduces waste.

- Data-Driven Insights with Machine Learning:

By analyzing time-series data from AM processes, our machine learning models classify and predict outcomes, such as weld quality and material behavior. These insights drive continuous improvement, ensuring precision in every manufacturing step. - Enhanced Cybersecurity and IT Infrastructure:

As manufacturing becomes increasingly digital, securing data and systems is paramount. CIDAM employs robust cybersecurity measures and IT infrastructure upgrades to protect sensitive information, ensuring a reliable and secure operational environment. - Automation and Smart Systems:

IoT-enabled devices and AI algorithms are integrated into robotic systems to automate complex manufacturing tasks. This reduces human intervention, minimizes errors, and increases production efficiency.

Key Benefits

Our AI & IoT initiatives offer numerous advantages for the maritime manufacturing industry:

- Improved Quality Assurance: Real-time monitoring and automated defect detection ensure high-quality outputs with minimal rework.

- Operational Efficiency: Automation and data-driven decision-making streamline production processes, reducing downtime and resource wastage.

- Predictive Maintenance: IoT sensors monitor equipment health, allowing us to predict and prevent failures before they occur, reducing unexpected disruptions.

- Sustainability: By optimizing processes and reducing waste, our AI & IoT solutions contribute to eco-friendly manufacturing practices.

- Enhanced Security: Advanced cybersecurity protocols protect critical systems and data, ensuring the integrity of operations.

Applications

AI and IoT at CIDAM are applied across various aspects of manufacturing:

- Additive Manufacturing (AM) Quality Control: Monitoring and optimizing parameters such as weld width, height, and deposition speed to ensure defect-free production.

- Integrated Sensors: Using IoT devices to capture data for performance analysis and real-time adjustments.

- Robotic Systems: Enhancing automation in tasks such as 3D printing, assembly, and finishing.

- Smart Infrastructure: Building a secure and connected manufacturing ecosystem that supports digital transformation.

Innovation in Action

Our AI & IoT projects exemplify how technology can transform manufacturing:

- Fault Detection in Metal Deposition: Using machine learning to identify defects like lack-of-fusion and non-filling during additive manufacturing processes.

- Edge AI for Real-Time Monitoring: Deploying low-latency, IoT-enabled AI solutions to improve the precision and reliability of AM systems.

- Cybersecure Operations: Implementing advanced security measures to protect sensitive design and manufacturing data from cyber threats.

Collaboration Opportunities

CIDAM is committed to using AI and IoT to shape the future of intelligent manufacturing. Whether you are seeking to improve operational efficiency, implement real-time monitoring, or enhance data security, we have the expertise to help.

Partner with us to explore the transformative potential of AI and IoT in manufacturing. Together, we can build smarter, more sustainable solutions for the maritime industry and beyond.